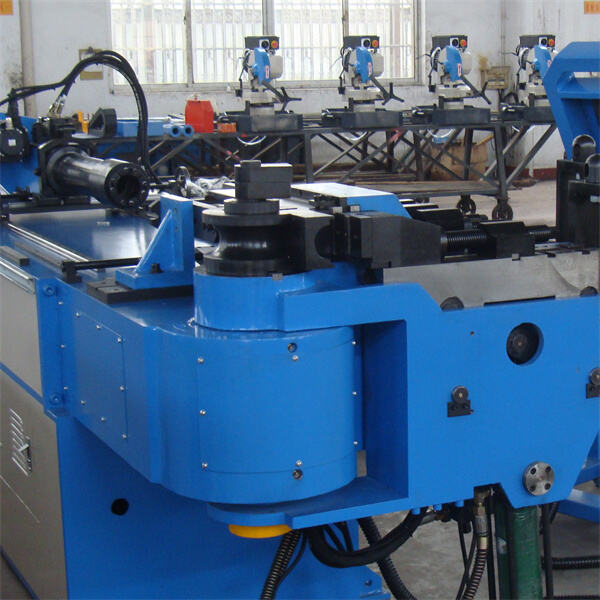

The latter refers to tools or devices used in factories especially pipe bending machines that help in bending the pipes/tubes into what are required shapes for different applications. The reason these machines are so useful in that they ensure the bends formed in the pipes or tubes is flawless. Their mandrel is a flexible rod or wire tool, unique to their setting. To ensure that the tube shape remains supported during bending, a mandrel is placed into the interior of the pipe. It is support having good outcome because it play role for not allow the tube get crushed or deformation of its shape when bend.

Mandrel Benders are made for producing smooth, tight radius bends without putting kinks in the tube. A mandrel is used to locate the tube first. This is important because it stops the tube from imploding. Later, the tube is moved along a fixture and wrapped around a form in the process known as bending die. When both clamp and die are used, they press on the tube to create a bend in it of the shape one desires. As the mandrel is within the tube, it prevents the tube from collapsing too much, or failing altogether to make sure that the bend looks and works properly.

One of the primary requirements for using a cnc pipe bending machine is that it should have very precise bends. So crucial as it denotes that all the parts produced are identical in size and form. Properly bent brackets generate less scrap as well. The factory not only saves time but also spares replacement. This machine can also be eliminated with the need for other tools or machines, reducing overall time of work along with cost. This is ideal for business as those factories can then product higher quality parts more quickly.

This makes them versatile since these machines can bend a variety of materials. Metals and plastics, as well as special composite materials were used in these metalworking processes. So they can do lots of different types of jobs, from building cars and planes, to making buildings. Factories can make things strong, long-lasting or rust-resistant by bending different materials. Manufacturers can use their versatility to please the demands of sectors and customers alike, with the ability to work across a range of materials.

Mandrel bending is really important in the construction process because it can give you shapes and angles required in the making that are very complex and absolute. This power to create geometrical shapes and angles also allows factories to build parts that can be easily assembled, fit collectively completely and have a superior functionality with regard to the meant software. In areas where your part bends, these machines can put up forms that another machine could not produce and allows for more design freedom. The high tolerance and quality of the parts manufactured mean less room for error in all end products.

In factories, a mandrel bending machine would save both time and materials. The exact bends that the machine can create mean there is less wasted material left when production spaces have to be cleaned up. A factory could save considerable money and time in the long term, cutting down scrap material by this percentage reduces waste signficantly. Most of these machines can also work independently, so there is less need for actual human labor. This kind of automation not only saves time, but reduces errors that can be made during the bending process.

For special needs pipe bending machine makers offer customized services that are designed and constructed according to the actual needs of the customers, ensuring that the accuracy as well as the angle and form of the bending pipe conform to the specifications of the item. This service is not just custom-designed to meet the requirements of the client but also improves the efficiency and quality of the product.In sum Pipe bending machine manufacturers give users effective safe, accurate and precise pipe bending options through their strengths in technological innovation efficiency, high-quality production, safety assurance, Mandrel bending machine and environmental protection, as well as tailored services to meet the requirements of various fields and industries.

Manufacturers of pipe benders take care to ensure the safety and protection of the operators in the process of designing. They adopt Mandrel bending machine, like safety grates safety gratings, emergency stop buttons, as well as infrared safety equipment, to ensure their safety throughout production. The equipment is also highly flexible to harsh conditions and will work efficiently within them. It provides the user with a confidence in the production.

By optimizing the production process and adopting modular design, pipe bending machine manufacturers are able to adapt the equipment to production Mandrel bending machine, dramatically increasing production efficiency. At the same time the control system's intelligent technology controls the manufacturing process in real time to ensure that the equipment is always in top shape and thereby increasing the efficiency of production.

In constant technological development, pipe bending machine manufacturers have developed advanced Mandrel bending machine, high-speed milling technology and sophisticated control systems that make the equipment more accurate and stable during the manufacturing process. The technological advancements improve the efficiency of production as well as the precision and quality of pipe bends. They also meet the requirements for processing of different complex workpieces.