Laser cutting tubes in the new age has developed into the most cost-effective method alongside having other benefits. This includes a very powerful laser beam which is used too cut the tube in an very safe an method.

Laser TUBES have a bunch of killer benefits number one being it soo accurate. The laser, using a targeted Computer Aided Design (CAD), will then cut any shape the tube without modifications. we can design in a higher detail level with this system. The second business — are the speed and cost cutting way of laser cutting tubes. Professionally performed laser cutting can achieve a comparable level of precision to traditional tooling and at high speeds, but at goes more quickly, and involves far fewer steps than older. which require a broad array of tools an setups for many different finishing requirements. Besides being very accurate, laser also cuts clean and with a smooth edge that does not need further processing.

Laser cutting pipes can be realized for regular design. As the new method of cutting do even more elaborate. shape and patter which is impossible through traditional means. And my friends are a complete game changer for our projects. We l

Various Industry use laser cutting tube, it’s not solely for Manufacturing. The most important fields an which airplanes, cars, and medicine serve. Laser Cutting helps the aviation sector. in generating needed designs and shapes of different parts and components of aircraft. Bending tubes is generally used in the following sectors:

accurate laser cutting of tubes (too confirm that the tubes is cut accurately with out waste). You can see that it will make us make more tubes faster. and this are one of the most important thing in mass production. And all of the latest technology. all computerized laser cutting machine at

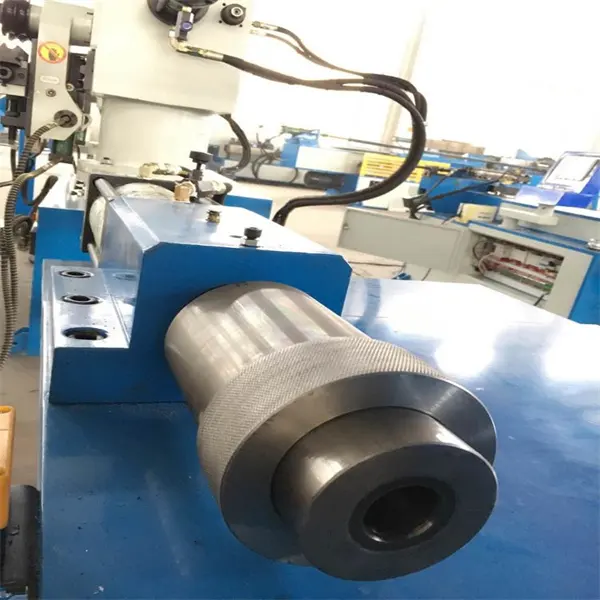

Laser cutting tube have become more accurate and stable in production because of the development of modern CNC technology high-speed milling technology and sophisticated control systems These advances in technology not only enhance the efficiency of production however they also guarantee the quality and accuracy of the pipe bend and meet the processing needs of various complicated workpieces

Pipe bending machines manufacturers offer tailored services to meet your specific demands. They can develop and produce the product according to the Laser cutting tube of the client to ensure that the accuracy, angle and shape of bent pipes meet the requirements of the product. This customized service not only fulfills the specific needs of customers, but also improves the production and quality of the item.In summary Pipe bending machine manufacturers provide users with efficient, accurate and safe pipe bending solutions by virtue of their technological innovations efficiency, high-quality production, safety assurance, energy saving and environmental protection, as well as personalized services, meeting the requirements of different industries and sectors

The manufacturers of pipe bending machines take care to ensure the safety and security of the workers in the process of designing They adopt multiple safety measures for example safety gratings Laser cutting tube and infrared safety devices to guarantee their security during production The machine is also capable of adapting to harsh environments and performs well in these environments This provides users with confidence in the production

Pipe bending machines can be Laser cutting tube to the requirements of production through adopting a modular design and optimizing manufacturing processes. This can greatly increase the efficiency of production. The control system is intelligent and monitors production in real-time to ensure that the equipment is in top condition. This increases the efficiency of production.