We take in daily life aluminum, this is a very important metal so to speak. AluminumYou might know that aluminum is an element in the periodic table and you can find it in many things around your home from soda cans, airplanes to large buildings. Aluminum can be used in a unique way and this is to take it and bend the metal into shapes, which is why they call them bent aluminum tubing. The Rewiring Process is not a simple process but has so many benefits and uses.

Creating aluminum bends serves a couple of purposes. Aluminum is in the first place lightweight, so it doesn't include a lot of weight that you need to haul and move. Strong: This will be able to carry a lot of weight without breaking. Third, the aluminum tubing is highly formable. So, now you know how useful bent aluminum tubing might be for a great number of jobs in numerous fields. There are countless applications for materials that are both strong and light, such as the planes themselves — also importantly due to their strength-fix (10 seconds you') Which is why bent aluminum tubing is a vital asset for these industries.

Bending an aluminum tube is never that easy. And it takes tremendous abilities and practices. Below are some of the other key factors involved in bending aluminum tubing. This allows you to determine what thickness of wireline tubing that you require, and guide you through the calculations so that you can pinpoint a particular shape. This detail seems pretty obvious, but it is crucial. If the tube is bent in an inappropriate manner, it leaves no room enough strength and may not be safe to use. This is why there is a requirement of skilful workers who can do bending safely and precisely.

When it comes to bending aluminum tubing, we are the experts here at GMACC. But bending has to be done properly and we take pride in our work. We bend the tubing in a manner that allows it to remain strong and dependable. We do this by deploying the best machinery and tools in the market, and a team of professionals who are well versed with every small thing that can make each tubing excellent. We take pride in the fact that every tube we produce is of utmost quality. Clients can rest assured as they receive material from DFT.

Bent aluminum tubing can be a great choice for so many different types of building projects. The benefits of this are that it can take any shape and be moulded to the specific demands of a project. From a little part to a huge structure, aluminium tubing could be adapted for such a demand. This is particularly useful for those pieces which have to be accurate and creative at the same time. Many times, wrought aluminum tubing is a strong solution for architects and engineers to realize their visions.

Given that every project is different and we aim to be flexible at GMACC. This is why we give our clients a choice to customize their bent aluminum tubing. As a direct marketing agency, we collaborate with our clients to gain insights into their end goals. This allows us to create tubing that fits perfectly on every project, no matter how unique and complex it is. We always want to cater and that with the final product of their order.

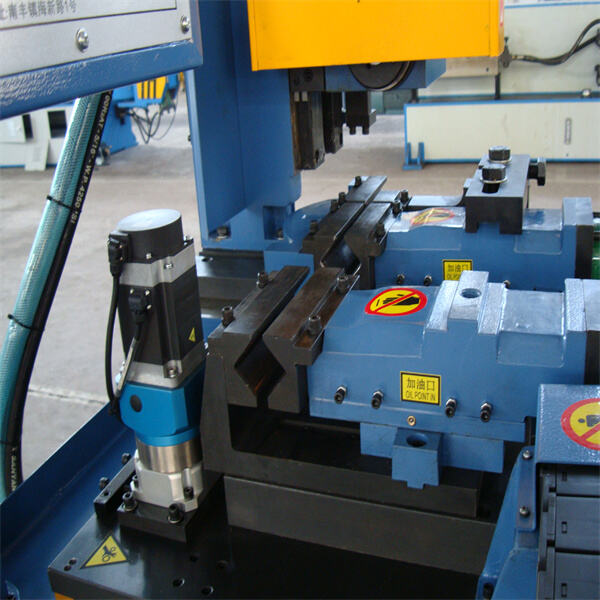

Pipe bending machine Bent aluminum tubing are attentive to the safety of operators throughout the design process and adopt multiple safety protection measures including emergency stop buttons safety gratings or infrared devices for protection to ensure the safety of workers throughout the manufacturing process Additionally the machine has a high degree of environmental adaptability and can operate stably in extreme environments providing customers with reliable production guarantees

Pipe benders manufacturers provide customized services to meet special needs. They are able to design and build according to the needs of the client in order to ensure that the angle, Bent aluminum tubing and design of bent pipes fully meets the specifications of their product. This service is not just tailored to the individual needs of the client but also improves the product's quality and efficiency.In sum Pipe bending machine manufacturers give users effective precise and secure pipe bending solutions based on their technological innovations effective production, safe security, energy efficiency and environmental protection and personalized services, meeting the needs of different industries and fields

Bent aluminum tubing have become more accurate and stable in production because of the development of modern CNC technology high-speed milling technology and sophisticated control systems These advances in technology not only enhance the efficiency of production however they also guarantee the quality and accuracy of the pipe bend and meet the processing needs of various complicated workpieces

By optimizing the production process and adopting a modular design pipe bending machine manufacturers can easily adjust the machine according to production demands, Bent aluminum tubing improving production efficiency. While at the same time the control system's intelligent technology controls the manufacturing process continuously to ensure that the equipment is in top condition and thereby increasing the efficiency of production.