Hey kids! The Induction Bending Machine, You Ever Heard about it? It's a very cool tool that can bend these pipes up to any shape or size. This super cool machine makes all of the pipes we offer so keep reading to get a little insight into how it works and what shapes you can create with it!

It is a machine that spends heat to bend pipes called the pipe bending machine. It is similar to bending a drinking straw, but only they are gigantic pipes! This machine warms a certain part of the pipe via that section getting soft. And when it is pliable, the machine can contort it in to the shape that we desire. Induction bending is a neat little process which helps to facilitate the pipework for you!

It is a quick and easy method of pipe bending called induction bending. Instead of heating the total pipe, as done by other approach, a very small section of the pipe is heated through it. It gets less hot, but actually works faster! Premises bent tube, This also means that there is less risk of damaging the pipe while it is being bent. In turn, it also helps keep the pipes brand new!

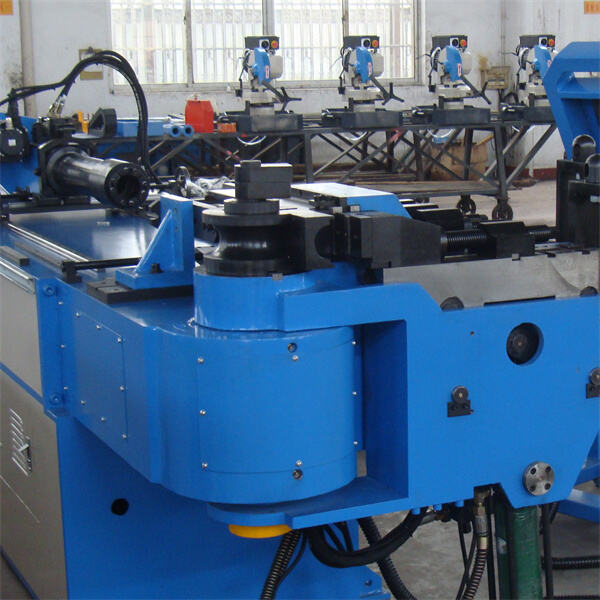

The cnc pipe bending machine can produce highly complex shapes in the bending jigs. This feature is extremely useful for a variety of businesses like oil and gas, construction and manufacturing among others. It can even manufacture curved metal parts for items such as furniture and cars. This makes it a power tool because it can be used in many areas of our lives.

The induction bending machine, is actually a unique commodity which could come with the ability to shape the pipe in any big element. E.g. can bend pipes in S, U & even Z forms! This is useful with special pipings, which need to be placed in some specific space or the particular means of connecting. This model can also bend pipes to various angles, allowing it to form either small or large bends. You should see it mould the pipes- like magic!

One of the most important things of an induction bending machine is its flexibility! It is able to bend many types of pipelines, from carbon steel to stainless steel and copper. This also means that companies can use one machine to process various types of pipes, thereby reducing costs and time. Rather than having to have multiple machines for different materials, they can simply come through one great machine that does it all!

Pipe bending machines have become more accurate and stable in production thanks to the advent of cutting-edge CNC technology high speed milling technology and Induction bending machine These innovations in technology improve the efficiency of production and also the precision and quality of pipe bending They also meet the requirements for processing of different complex workpieces

For special needs pipe bending machine makers offer customized services that are designed and constructed according to the actual needs of the customers, ensuring that the accuracy as well as the angle and form of the bending pipe conform to the specifications of the item. This service is not just custom-designed to meet the requirements of the client but also improves the efficiency and quality of the product.In sum Pipe bending machine manufacturers give users effective safe, accurate and precise pipe bending options through their strengths in technological innovation efficiency, high-quality production, safety assurance, Induction bending machine and environmental protection, as well as tailored services to meet the requirements of various fields and industries.

Pipe benders take care to Induction bending machine the safety of their operators when designing the machine and adopt multiple safety protection measures including safety gratings emergency stop buttons and infrared protection devices to ensure the safety of employees while they are working Furthermore the machine is also highly adaptable to environmental conditions and can operate stably in various difficult environments providing the users with reliable production guarantees

Pipe bending machines can be Induction bending machine to the requirements of production through adopting a modular design and optimizing manufacturing processes. This can greatly increase the efficiency of production. The control system is intelligent and monitors production in real-time to ensure that the equipment is in top condition. This increases the efficiency of production.