GMACC Custom Metal Bending Machinery They are used for a variety of metals A few of the metals they work with welded include stainless steel, Aluminum, Copper and Carbon Steel. The bends are repeatable, and the GMACC uses smart technology and some of the best materials to make sure they're smooth–an imperceptible small kink in a pipe can lead to crack much later on in a significant metal component, taking down an entire production line.

The pipe bending machines of GMACC can be considered as flexible and adjustable. This means they will be able to assist with fabrication of custom metal parts that adhere perfectly to your distinct requirements. Engineers can create and manufacture a wide voyage of shapes and sizes in metal pipes with the help of specific bending software. That ability enables GMACC's systems to be used across a wide range of industries -- automotive, aerospace, architectural and commuter transportation among them. They can be used for anything from producing a one-of-a-kind part for an automotive to creating the missing piece on the fly in construction.

One of my favorite things about the GMACC machines is that they are designed to make work easier and more efficient. Through the use of these machines, you can save money and time in the production process. These templates are what is known as production-ready, they will help companies shave off time from their production process. Which can save a lot of labor overhead and time. These machines make it possible for you to produce more in less time, allowing you to keep up with customer orders. This speed works to your advantage by giving your business a competitive edge in today's market.

The pipe bending machines at GMACC are all advanced and smart technology focused which means you can trust that the bends will be accurate and consistent each time. The software on the machines take care of how each bend is performed, so all bends are precise. This technology significantly reduces the probabilities of errors which can occur during manual human operations. This ensures that the final product is of excellent quality and can satisfy even the most demanding consumers. GMACC machines delivers a piece that is exactly what you want to get.

The pipe bending machines developed by GMACC are high quality, durable functioning and reliable over the long term. These devices can be used for a considerable range of bending operations. The accessible have also put in place to deal with large workloads while keeping pace. Moreover, these machines are low maintenance as well and you will not have to pour money for its upkeep. This way, you can concentrate on your work without worrying about problems or downtime. Choose GMACC for all of your custom metal needs, because their machines are reliable and fast.

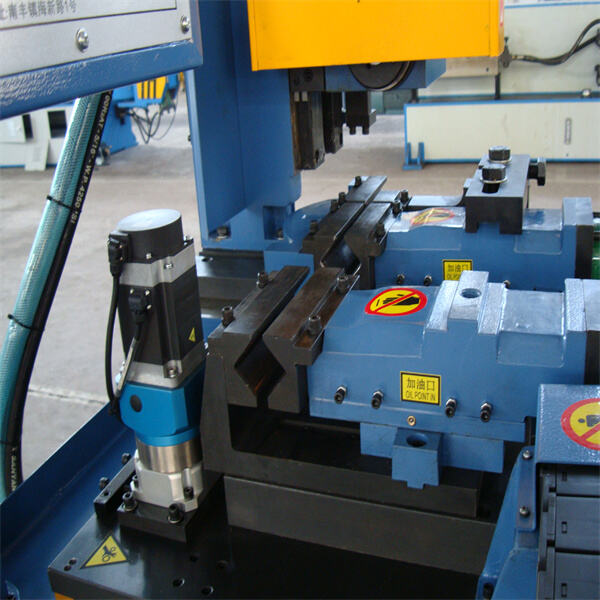

The manufacturers of pipe bending machines take care to ensure the safety and security of the operators in the Industrial pipe bending machine. They employ a variety of security measures, including safety gratings or emergency stop buttons as well as infrared safety devices, to ensure their safety during production. The equipment is also highly adept to harsh environments and is able to work effectively within them. This gives users a the assurance of production.

Pipe bending machines are more reliable and Industrial pipe bending machine in production because of the introduction of advanced CNC technology, high speed milling technology and sophisticated control systems. The technological advancements improve the effectiveness of production, as well as the accuracy and quality of the pipe bends. They also meet the processing requirements of various complicated workpieces.

Industrial pipe bending machine manufacturers provide tailored services to meet your specific specifications. They are able to design and manufacture in line with the requirements of the customer to ensure that the angle, accuracy and design of bent pipes completely meet the requirements of their product. This custom-made service not only fulfills the specific needs of customers, but also improves the production and quality of the product.In summary Pipe bending machine manufacturers provide users with efficient, accurate and safe pipe bending solutions by virtue of their benefits in technological innovation efficiency, high-quality production, safety security, energy efficiency and environmental protection, and tailored services to meet the requirements of different industries and sectors

By optimizing the Industrial pipe bending machine and adopting a modular design pipe bending machine makers can adapt the equipment to production needs, drastically increasing the efficiency of production. In addition the control system's intelligent technology monitors the process of production continuously to ensure that the equipment is always in good working order and thereby increasing the efficiency of production.