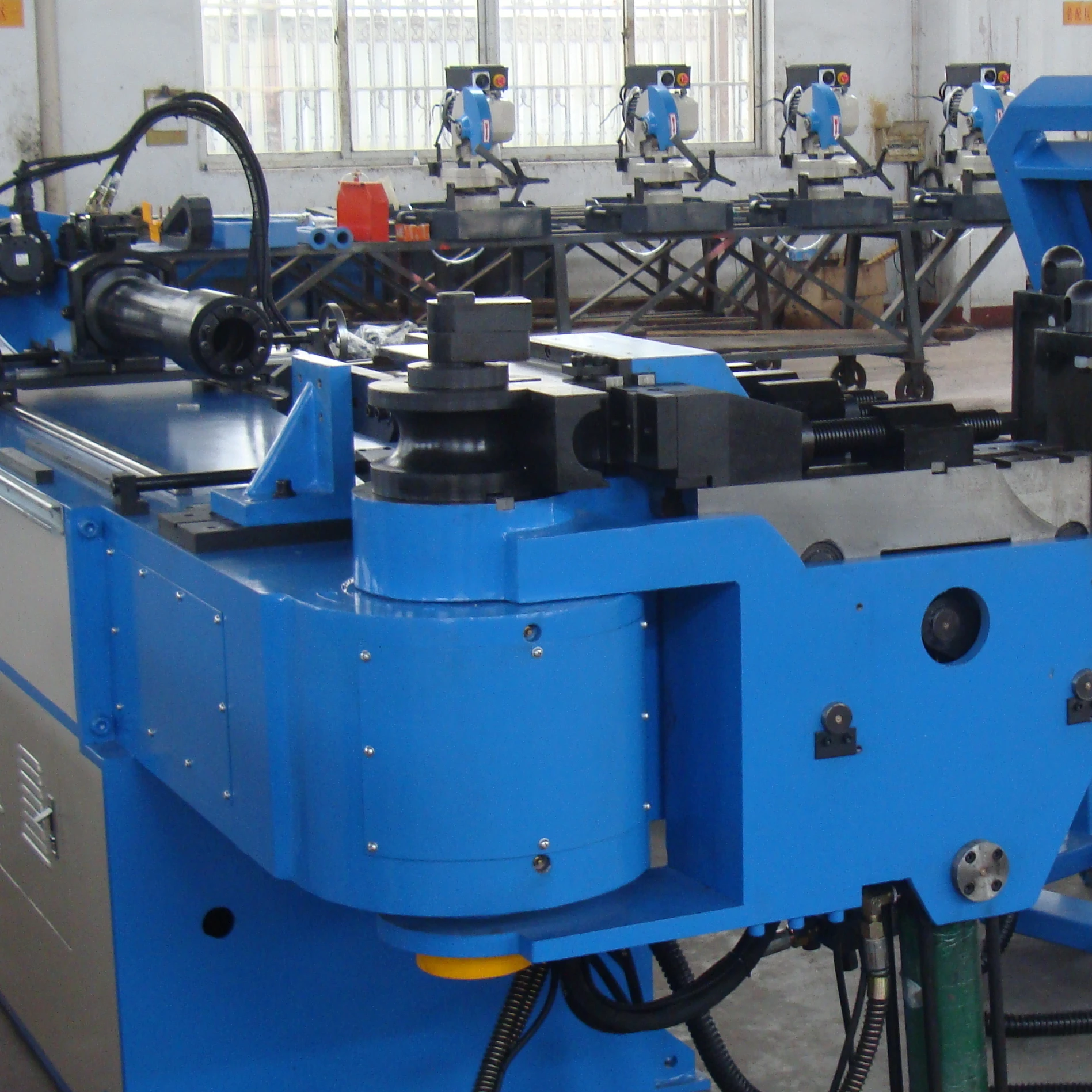

These machines are intelligent and aid workers in the ability to bend pipes quickly and safely. GMACC is a manufacturer that makes these machines, and it’s very good at them. The CNC technology ensures that bending pipes is faster and with less effort. That is less mistakes and a good thing for all concerned. Workers have the time to concentrate on other important jobs while the machine does all of the hard bending work. This is better for companies that are about the business of pipes.

What Are the Advantages of Buying CNC Pipe Bending Machines Wholesale?

CNC pipe bending machines have many advantages for wholesale customers. For one thing, these machines save a lot of time. Rather than bending machine by hand, a time-consuming process that is often fraught with error, CNC machines merely get on with the job in super-quick form. For wholesale buyers, that means faster delivery times. Faster pipes help companies sell to customers faster, which is good for business as a whole. Additionally, CNC machines are highly accurate. This minimizes the pipes coming out being shredder-width. Wholesale customers don’t need to worry about getting pipe that’s too large or small. This accuracy can also enable them to steer clear of the costs associated with returns or rework. A second advantage is that these machines can process varying materials. No matter if the piping is steel or aluminum (or something else), a CNC machines can bend them all. This flexibility makes it easier for wholesale buyers to find what they want without needing to find multiple sellers. Lastly, CNC machining with technical quite make the work safer. Workers are not required to apply heavy tools that pose danger of injuring themselves in the process of bending pipes. They do not have to be physically close to the CNC machine, they can control it at a safe distance. That translates into less mishaps and a safer working environment. In the round, CNC pipe bending machines make wholesale buyers’ lives easier and safer.

The Game Changer - Why Is a CNC Pipe Bending Machine Considered As One?

There are number of ways, CNC pipe bending machines that's how. For one, bending is much quicker to execute. Bending pipes the old-fashioned way can be time-consuming, yet with CNC, it can take mere minutes. This speed is imperative for shops that have strict deadlines. Plus, the machines are capable of bending pipes in an array of shapes and angles. This enables fabricators to produce custom plate shapes as required for many work projects. From pipes installed in buildings, to those found inside cars and even furniture, CNC machines can produce everything. Another major consideration is that these machines lessen waste. Hand-bending pipes can leave a good amount of scrap material that isn’t usable. But CNC machines are so efficient that less scrap is created. It’s not only more cost-effective and better for the environment. It can also reduce the physical impact on workers by using CNC machines. Bending pipes by hand in the past could be strenuous labor that led to injury. Now employees can use machines to do the heavy lifting, and work is safer and more fun. Finally, with the precision of CNC machines, fabricators can have confidence their product will be produced with integrity and the same way every time. This fosters stronger customer relationships, since customers trust that the work is going to be of high quality. To sum it all up, CNC pipe benders are a game changer for the fabricator in that they enable you to complete your projects even faster, safer and more accurate than ever before.

How to Choose the Right CNC Pipe Bending Machine for Your Needs

CNC pipe bending machines are integral accessories that aid in shaping pipes for various industries. They speed up and protect the pipe-bending process. When Anyone plan to purchase CNC pipe bending equipment, it is important for knowing how to select the best one according to their requirement. First of all I would carefully consider what the size of pipe you want to bend are. Some machines accommodate larger sized pipes, while others are designed for smaller. Make sure to choose a machine that suits the type of work you do. You also need to think about what you’ll be working with. Some materials are better on some machines than others, such as steel or aluminum. Now consider the power of the machine. Some CNCs can tube bend in a number of angles and shapes, while some may be limited. If you have complex designs in mind, however, find a machine with more features. Another factor to take into account is its user friendly. There are more intuitive ones, so newer operators can learn more easily. Finally, remember, that you get the support and service of company you buy from. GMACC has top-notch customer service, which can come in handy if you face any issues with your machine.

Tips for Finding Affordable CNC Pipe Bending Machines in Bulk

Searching for inexpensive CNC pipe bending machines in wholesale quantities is not the easiest task, but there are a few ways you can make it easier. Begin by doing some research online. Machinery-specific websites usually list multiple suppliers and their prices. Monitor prices across different locations to get the best deals. You may also visit trade shows and fairs. These shows can display new machines and equipment, and you might find special deals that are not listed online. It is more difficult to ask questions about the machines and get a real sense of their quality if you only meet suppliers online. Alternatively, you can contact GMACC directly. And they tend to have wholesale, so you would get good price. Check if the supplier provides warranties or guarantees on their machines. This should provide you with confidence that you are in a safe investment. Finally, don’t be afraid to ask people in your industry for referrals. Those with experience have useful tips on where to purchase good machines at affordable price.

Emerging Trends in CNC Pipe Bending Technology

The world of CNC pipe bending seems to change on almost a daily basis, and there are some interesting trends that you’ll want to follow. One of the newer trends is smart technology. Today most new machines have the capability of being connected to the internet. This allows them to communicate information and updates with one another, helping operators easily keep track of what work is being carried out. Another trend is down to the emphasis on energy efficiency. New machines are being developed that draw less power and can still deliver top performance. That is good for the environment and can help save on energy costs. On top of this, the appetite for automation is increasing. An increasing number of businesses are turning to automate their pipe bending process to improve its speed and decrease the likelihood for human error. We realize the changing needs and GMACC provides equipment to keep pace with these changes. Training and safety systems are also getting better. New generations of machinery often have improved safety systems to shield workers during work. With advancements like these, come progress for CNC pipe bending machines to be utilized more efficiently and safely by all who deal with fabricating.

Table of Contents

- What Are the Advantages of Buying CNC Pipe Bending Machines Wholesale?

- The Game Changer - Why Is a CNC Pipe Bending Machine Considered As One?

- How to Choose the Right CNC Pipe Bending Machine for Your Needs

- Tips for Finding Affordable CNC Pipe Bending Machines in Bulk

- Emerging Trends in CNC Pipe Bending Technology

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

CA

CA

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

SQ

SQ

ET

ET

GL

GL

HU

HU

MT

MT

MS

MS

SW

SW