There might have been times when you wanted to create wire shapes for your crafting items or projects. Perhaps you wish to create a unique item such as jewelry or any other wonderful décor for your place. Fnally, you can with the GMACC easy wire bender DIY guide to do-it-yourself and save some of your hard earned money! Today in this guide, we are here going to tell you simple steps on How To Make Your Wire Bending Machine at home. We will also tell you why DIY works is a pleasurable and rewarding experience.

Make sure that all the materials you need will be easily found in a hardware store near you. You need to accumulate all of this: a wooden board, a metal bar, a drill, screws, saw and wire cutters. Most hardware stores will sell these items and they are only a few dollars at most. So, here are steps that you can follow after having everything ready!

Then, cut the metal bar to four times the length of the wooden board. It does create a decent amount of length for you to play with &you should be able to make quite a few wire shapes easily.

After you cut the metal bar, insert it into the two holes of the board so that an equal amount of bar sticks out on both sides. This will be the section of the part that you bend the wire over.

By now, you should have your wire bender good to go so that you can already put it into use for different wires shapes in case you need it for your other wire projects. Ideally, you can produce beautiful jewelry with a little imagination and creativity or unique decorative ornaments or even a select few pieces of small furniture! They are great, too, because you can create all sorts of shapes that normal benders just could not make. In other words, only you will have what you make!

Customize your wire shapes, with GMACC's DIY wire bender Create your own style, experiment with different types of wire (colors, and thickness) It is an excellent opportunity to showcase your personality and style. It helps to avoid challenges of finding the right shape from store also because you get exactly what you want!

Circling WireIn this article from Step 1, it is not free to make your own wire shapes, even very versatile as one of the beneficial ways ashes and frugal in my opinion. No longer do you have to purchase expensive premade shapes from the store. You will be able to make what you want for your project, instead of needing to purchase an entire-wing-set of wire shapes. This means you can spend less and still have what you need to run with your creative thoughts.

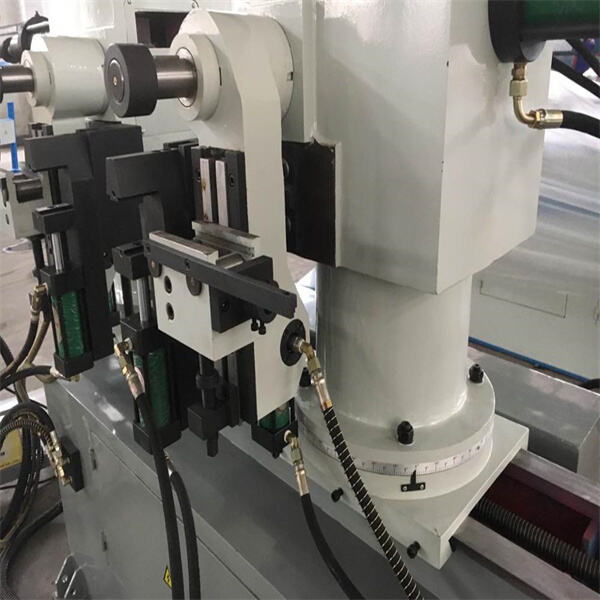

Pipe bending machine manufacturers focus on the safety and Wire bender diy of the workers in the design phase. They employ a variety of security measures, including safety grates safety gratings, emergency stop buttons, as well as infrared safety devices to guarantee their security throughout production. In addition, the equipment is also highly adaptable to environmental conditions and is able to function safely in various conditions, providing customers with confidence in their production.

Pipe bending machines can be Wire bender diy to the requirements of production through adopting a modular design and optimizing manufacturing processes. This can greatly increase the efficiency of production. The control system is intelligent and monitors production in real-time to ensure that the equipment is in top condition. This increases the efficiency of production.

For special needs pipe bending machine makers offer customized services that are designed and constructed according to the actual needs of the customers, ensuring that the accuracy as well as the angle and form of the bending pipe conform to the specifications of the item. This service is not just custom-designed to meet the requirements of the client but also improves the efficiency and quality of the product.In sum Pipe bending machine manufacturers give users effective safe, accurate and precise pipe bending options through their strengths in technological innovation efficiency, high-quality production, safety assurance, Wire bender diy and environmental protection, as well as tailored services to meet the requirements of various fields and industries.

Pipe bending machines have Wire bender diy more reliable and precise in production because of the advent of cutting-edge CNC technology high-speed milling technology and sophisticated control systems These advances in technology not only improve production efficiency however they also guarantee the quality and accuracy of the pipe bend and satisfy the needs for processing of different workpieces