To that end- Do you need a useful tool to make roll hoops? If that is the case, GMACC 's range of pipe tubing benders from roll cage makers are just for you! If you enjoy building and making things, this is a tool that is made to be both easy and enjoyable to use.

Bend steel pipe with ease and the GMACC roll bar pipe bender This wonderful tool easy enough even for kids who love to play builder scientist. First, put the steel pipe in the bender to get it all set up. It is then a simple matter to rotate the handle to produce your desired bend. It’s that simple! Gone are the days of clunky, difficult to use tools. You can then spend all your attention on getting your project spot on!

This GMACC roll bar pipe bender is meant to deliver pro level results any time you incorporate it into a project. No matter if you are working on a race car, an off-road car or any other vehicle that needs a roll bar done, this tool is here to get the exact shape of what you have in mind. In addition, it is very user friendly: this way you get these incredible results with relatively little effort. You will be surprised at how good roll bars you can make in no time!

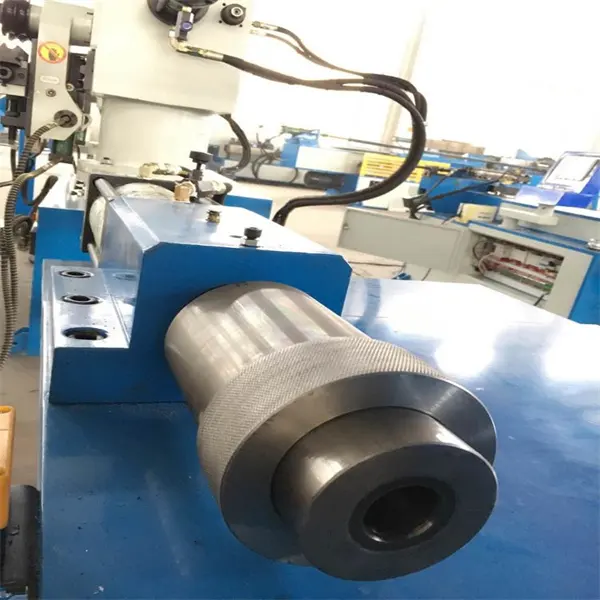

Built to lastAnd that is one of the best qualities about the GMACC roll bar pipe bender. Constructed of high-quality materials, which make it a much stronger and longer lasting pipe bender than other tools. Through this solidly build you be trustworthy an expand on all your roll bars jobs next long time. You never have to worry that it will break down or wear out!

A nice feature of the GMACC roll bar pipe bender, aside from saving lots of money, is being able to make a roll bar exactly the way you want it. This can help provide the Perfect bend every time especially if you are looking for a particular shape or size. The tool is easy to work with as well so having these customizations isnt a problem at all. In other words, you get more time to appreciate your projects and less of a headache from the tools!

One of the nice things about a GMACC roll bar pipe bender is that it rolls bars exactly as they should always be rolled. If you are a pro wrencher or into fun-builds, then making your custom roll bars is easy. When you have confidence in your roll gage, you can hold your head high with pride of having one | all their essential parts with full capabilities and no weaknesses.

With Roll bar pipe bender technological advancement pipe benders have introduced modern CNC technology as well as high-speed milling technology and intelligent control systems making the machine more precise and stable during the production process These advancements in technology do not just increase the efficiency of production but also ensure the quality and precision of the pipe bending and fulfill the demands for processing of different workpieces

Roll bar pipe bender manufacturers provide tailored services to meet your specific specifications. They are able to design and manufacture in line with the requirements of the customer to ensure that the angle, accuracy and design of bent pipes completely meet the requirements of their product. This custom-made service not only fulfills the specific needs of customers, but also improves the production and quality of the product.In summary Pipe bending machine manufacturers provide users with efficient, accurate and safe pipe bending solutions by virtue of their benefits in technological innovation efficiency, high-quality production, safety security, energy efficiency and environmental protection, and tailored services to meet the requirements of different industries and sectors

Pipe benders can be easily modified to meet the demands of production by adopting a Roll bar pipe bender and optimizing manufacturing processes. This can greatly increase the efficiency of production. While at the same time the computerized control system is monitoring the production process continuously to ensure that the equipment is in top shape and thereby increasing the efficiency of production.

Pipe bending machine manufacturers focus on the safety and protection of their workers during the designing phase They implement a variety of security measures including safety grates or emergency stop buttons as well as Roll bar pipe bender to ensure their safety throughout production In addition the equipment also has strong environmental adaptability and is able to function safely in extreme environments providing customers with confidence in their production