If you have ever observed an HVAC system, then you probably would not have missed the number of pipes. Air and liquid flow through these pipes to allow the transfer of energy throughout a building. Most of them had to be bent differently so that they could fit in different places. The following is the reason why such an HVAV pipe benderplay such a heavy role. GMACC's HVAC pipe bender is a tool that can eliminate the repetitive need for workers to shape pipes as they are very good in bending tubes.

For the workers of an HVAC, an HVAC pipe bender is truly necessary. This allows them to bend pipes that will fit in very small places which make their work easier and is much more efficient. The GMACC HVAC tube bender can bend pipes up to 90 degrees. This ensures that pipes will be able to slot perfectly into their designated places, without any twists or kinks which may cause issues further on down the line.

Correct pipe bending is essential for a better flow of air to provide better performance with the Heating, Ventilation and Air Conditioning systems Failing to bend pipes properly will cause poor flow of air and liquids, this could fail the entire system after a certain period of time. This leads to wear and tear and is inefficient. Crucially, the GMACC HVAC pipe bender, enables workers to bend pipes perfectly ensuring that an entire system operates more smoothly and has a longer life.

When it comes to installing HVAC systems, precision and accuracy are just as important as the overall functionality of the system. GMACC's HVAC pipe bender allows workers to bend each of these pipes just right. This will ensure that everything goes where it is supposed to go. Properly bent pipes improve the longevity of an HVAC system and decrease the frequency of repairs. Which means workers have to do less fixing and more getting the job done right.

Time is money as they say, and in the HVAC world every minute matters. Fast and efficient pipe bending thanks to GMACC's latest HVAC pipe bender. This will not only save them time but allow them to work in a more efficient manner as well. Customers are happy because their products or service can be delivered faster, and the organization benefits by increasing revenue. A happy customer is more likely to come back for more sales and also refer the service to another person.

Pipe benders manufacturers provide customized services to meet special needs. They are able to design and build according to the needs of the client in order to ensure that the angle, Hvac pipe bender and design of bent pipes fully meets the specifications of their product. This service is not just tailored to the individual needs of the client but also improves the product's quality and efficiency.In sum Pipe bending machine manufacturers give users effective precise and secure pipe bending solutions based on their technological innovations effective production, safe security, energy efficiency and environmental protection and personalized services, meeting the needs of different industries and fields

By optimizing the production process and adopting a modular design pipe bending machine manufacturers can easily adjust the machine according to production demands, Hvac pipe bender improving production efficiency. While at the same time the control system's intelligent technology controls the manufacturing process continuously to ensure that the equipment is in top condition and thereby increasing the efficiency of production.

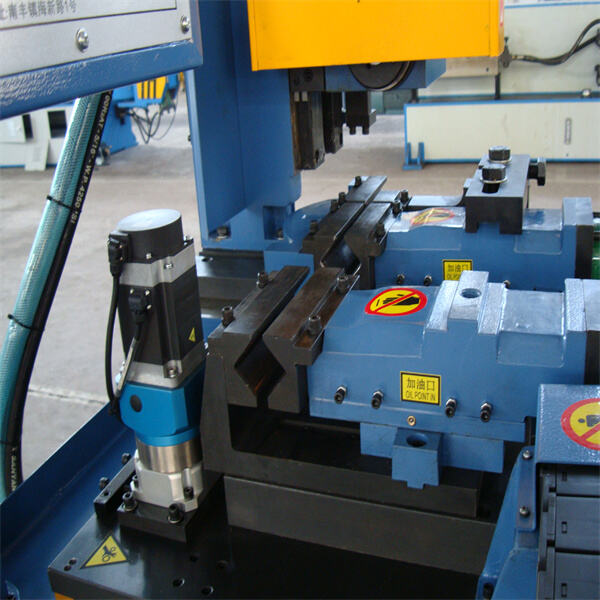

Manufacturers of pipe benders take care to ensure the safety and protection of the operators in the process of designing. They adopt Hvac pipe bender, like safety grates safety gratings, emergency stop buttons, as well as infrared safety equipment, to ensure their safety throughout production. The equipment is also highly flexible to harsh conditions and will work efficiently within them. It provides the user with a confidence in the production.

Pipe bending machines have Hvac pipe bender more reliable and precise in production because of the advent of cutting-edge CNC technology high-speed milling technology and sophisticated control systems These advances in technology not only improve production efficiency however they also guarantee the quality and accuracy of the pipe bend and satisfy the needs for processing of different workpieces