You do want to provide your customers the highest quality products that you can get. End Sealing Keeping your products fresh and tasty is another feature that nofrillseo will offer. So, what is end sealing? That means sealing a package up to this very end. This special seal keeps all the contents inside fresh and free from contamination.

End sealing seems pretty darn important with food products! Why is that? In fact, it is used to keep out air, with its moisture and small germs such as bacteria from entering the packaging listening on«']) These can enter and spoil the food more faster. It is because all well-wishers want this precious food to good for a longer time. Freshness & Food Safety are important to you, so it is also important to us at GMACC. And that is why we have started to use end sealing in our packages. We strive to deliver your food items in top quality, every time.

End sealing will also be useful for long-term supply of many products, especially those are able to be affected by air pollution, moisture and germs. We ensure fresh your product for the long duration with End Sealing. This not only benefits your customers but saves you money as well. How? Because if your products have a longer life, you are making less waste while selling the product for a more extended period. It is a win-win for all!

One of the largest engineering challenges that can plague with the manufacture and packaging of products is contamination. Contamination: This is when stuff can end up in the product that should not be there Ingredients or things. An example of this is if nuts ended up in a product which did not have nuts normally, people who are allergic to nut would then get ill after eating it and could even die. Reduces the OccurrenceThis is where end sealing comes in and helps protect your products It forms a good barrier to offer effective protection from air, moisture, and germs into the package. Our sealing machines and processes are of the highest quality to ensure that your products can remain free from contamination at all times. We strive to limit potential risks and preserve the state of your products.

The ability to end seal also allows the release of less precious hydrogen and helps eliminate leaks. Sure, nobody wants spilled everywhere during shipping but come on… Your goods are trapped around a tough package whenever end sealing This is all to insure 100% no spill, leak, or accident during transport. Customers can end seal their products, for added security by creating a well-sealed package sometimes manufactured together with top quality packaging solutions at GMACC. Rest assured knowing your belongings will arrive safely wherever you need.

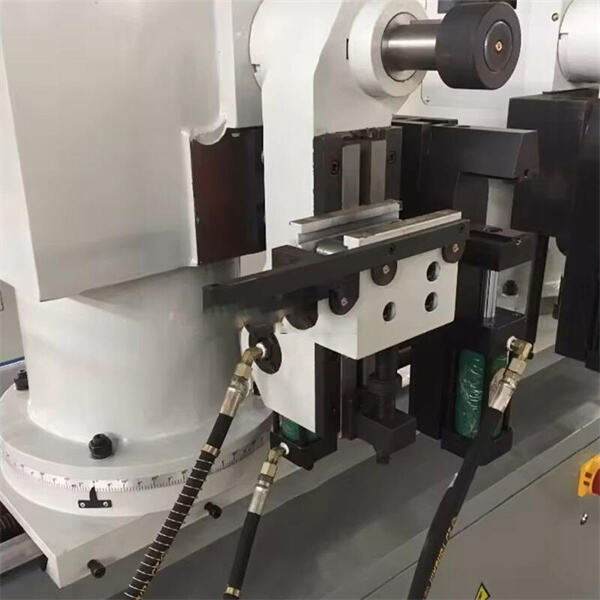

End sealing optimizing the manufacturing process and adopting a modular design pipe bending machine makers can flexibly adjust the equipment according to production needs, drastically increasing efficiency. The smart control system continuously monitors production to ensure that the equipment is running in top shape. This increases the efficiency of production.

Pipe bending machines are more reliable and End sealing in production because of the introduction of advanced CNC technology, high speed milling technology and sophisticated control systems. The technological advancements improve the effectiveness of production, as well as the accuracy and quality of the pipe bends. They also meet the processing requirements of various complicated workpieces.

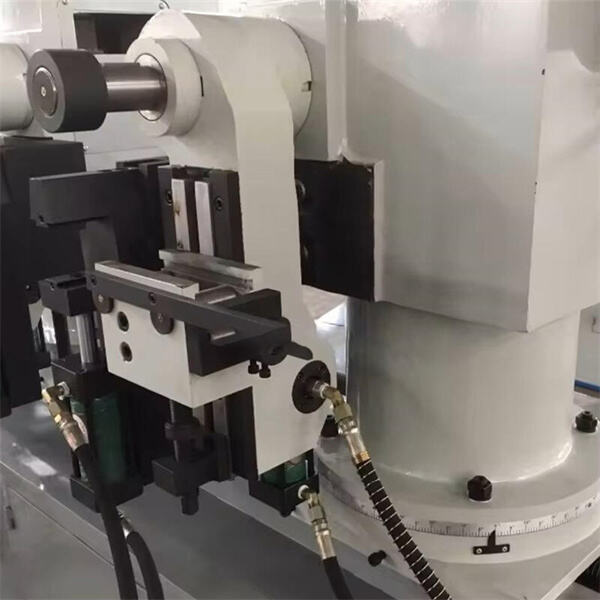

Pipe benders take care to End sealing the safety of their operators when designing the machine and adopt multiple safety protection measures including safety gratings emergency stop buttons and infrared protection devices to ensure the safety of employees while they are working Furthermore the machine is also highly adaptable to environmental conditions and can operate stably in various difficult environments providing the users with reliable production guarantees

Pipe bending machine manufacturers provide personalized services that meet particular demands. They can develop and produce the product according to the needs of the client, ensuring that the End sealing, accuracy and design of bent pipes are in complete alignment with the specifications of the product. This service is not just designed to meet the needs of the customer however, it also improves the efficiency and quality of the product.In short Pipe bending machine manufacturers provide users with efficient safe, accurate and precise pipe bending solutions based on their advantages in technological innovation, efficient production, safety security, energy efficiency and environmental protection and personalized services, meeting the demands of different fields and industries.