Do you know how they get pipes to bend around buildings or bridges? This was back when people had to do it all by hand! The pipes required a good deal of muscle to bend in the right way and were fragile. This made the operation cumbersome and time-consuming. We now have pipe bending machines which means you can bendelliptical tubes much faster and easier. Electric technology enables these machines to perform the best and efficient. Electric pipe bender machines of GMACC tell you how convenient and cool this technology is. Are the shaping as to what we can craft a pipe out of changing?

Indeed, cnc pipe bending machines will significantly increase the speed of processing pipes; moreover, they are far more precise. Doing everything this way they can bend the pipes at the right angles and perfect bends. If pipes are bent the wrong way it will cause problems for the entire building or structure. Machines like those from GMACC are able to bend pipes to extremely high levels of precision, as fine as a single degree. This ensures that the pipes fit together properly so they last longer without any issues. Also you will save time and there is less chance of failure since you do not have to fix or throw away pipes that was bend in wrong way by using electric machines. Which in result, there is a lot less material wasted; good for the environment!

Electric pipe bending machines work well in places for fabricating many pipes such as industrial premises or construction sites. Also, these machines can perform a high number of orders in very little time and perfectly. This helps companies to run more pipes in less time, which is crucial when demand is high. The electric pipe bending machine by GMACC has various types to suit whatever you need in factories or for your construction project. The right machine makes workers take their cigarette breaks more efficiently and safely.

There are applicable rules in factories and construction sites on how pipes must be bent so that it is safe and of good quality. Electric pipe bending machines available from GMACC are compliant with these rules, which makes them a viable option for businesses. Robots are designed with safety in mind and to be easy for workers use. This means they are manufactured to the specifications of the regulations as well as what is wanted by the customer. Maintaining the sense of balance is a crucial in order to apprise everyone and not make them feel left out. [ getService>Nuggets ] Electric machines assist with ensuring the pipes constructed are of good quality, have long life, and offers their customers what they desire.

Intelligent electric pipe bending machine such as GMACC is fast, accurate and safe. They allow businesses to make a shit ton of pipes which gravel more revenue. Meanwhile, when businesses use electric machines, they save time and resources allowing them to make more profit. A must-have in today's hyper tempo world where time is money. Electric machines are also environmentally sound and we need to remember earth.Runtime Customers see eco-friendly technology as a way to show companies care about both the environment and what their customers value.

Pipe bending machines are more reliable and Electric pipe bending machine in production because of the introduction of advanced CNC technology, high speed milling technology and sophisticated control systems. The technological advancements improve the effectiveness of production, as well as the accuracy and quality of the pipe bends. They also meet the processing requirements of various complicated workpieces.

For customers with special needs, pipe bending machine manufacturers offer customized services that can be Electric pipe bending machine and manufactured according to the actual needs of the customer to ensure the accuracy, angle and shape of the bending pipe conform to the specifications of the product. This service is not only tailored to the individual needs of the customer and can also enhance the efficiency and quality of the product.In sum the pipe bending machine manufacturers provide users with efficient, accurate and safe pipe bending solutions by virtue of their technological innovations effective production, safe assurance, energy savings and environmental protection, and tailored services to meet the requirements of various industries and sectors

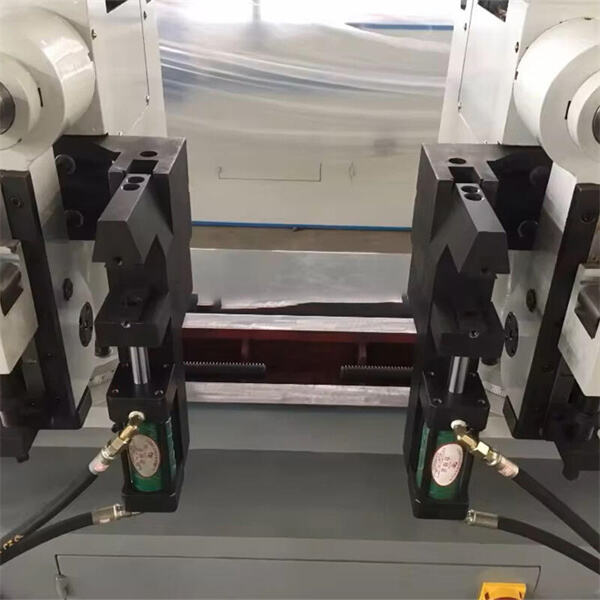

Manufacturers of pipe benders take care to ensure the safety and protection of the operators in the process of designing. They adopt Electric pipe bending machine, like safety grates safety gratings, emergency stop buttons, as well as infrared safety equipment, to ensure their safety throughout production. The equipment is also highly flexible to harsh conditions and will work efficiently within them. It provides the user with a confidence in the production.

Electric pipe bending machine optimizing the manufacturing process and adopting a modular design pipe bending machine makers can flexibly adjust the equipment according to production needs, drastically increasing efficiency. The smart control system continuously monitors production to ensure that the equipment is running in top shape. This increases the efficiency of production.