Copper benders are tradesmen who bends copper pipes for use in the plumbing and heating systems. It's like artists, but instead of paint and canvas they use copper pipes and tools. They bend the copper tubing to form curves, angles and bends in order for it to fit at the appropriate places inside residential and commercial establishments.

Copper pipes – Copper is a widely used material when it comes to pipe making, and that is due to the fact that copper is strong; can carry both heat and pressure well; without having any signs of breaking down. Because of this, they are the perfect support for plumbing and heating systems. Copper benders are those who get these pipes and turn them into functional alternatives as well as appearances. These guys are there to make sure that the pipes work well, aside from making them look artistic.

In other words, a copper bender; face it- It is a straight and very solid piece of copper pipe. Next, they form this straight pipe into the desire shape of a simple bend or complex tubing depending on their designs. They rely on special tools such as bending irons and hammers to shape the copper. They use these tools to get the shapes they must have, without weakening or damaging the pipe.

Copper benders have a tremendous sense of pride in the work they do. They practice all the time to improve on their skills and have to know how does copper reacts with heat and pressure. Hours are spent perfecting the technique — ensuring every piece is not only functional, but also beautiful. It is their passion and commitment to what they do that makes get work better.

One of the things that will make you rave about copper bending is that with this skill, these expert artisans can create unique designs which are mostly impossible through other metals. This includes things like: SpiralsWeavingCoilsMany more shapes and configurations. These designs have a dual purpose; they are functional in keeping interiors saving and also have fabulous appearances, allowing them to look stunning in both commercial or home projects. Copper work is appreciated by many for its beauty and can give an extra charm to any place.

Flexible busing elements are versatile, mobile and suitable for any architectural object, and can be supplied for heating systems, ventilation systems or water supply. They can also create ornamental features, such as handrails or copper sculptures. These are records that can add real beauty to a room while also serving practical purposes.

When it comes to copper benders, we have the best in the business here at GMACC. Our tradesmen are highly skilled in the art of forming copper piping. We only use top-quality materials and developers to create every project The project has been done correctly the first time and give satisfaction our clients. All our clients across the globe choose us to handle their copper bending requirements as they trust that we will serve them in the best possible manner with excellence work unless this all done can you happy or satisfied with what you are paying for.

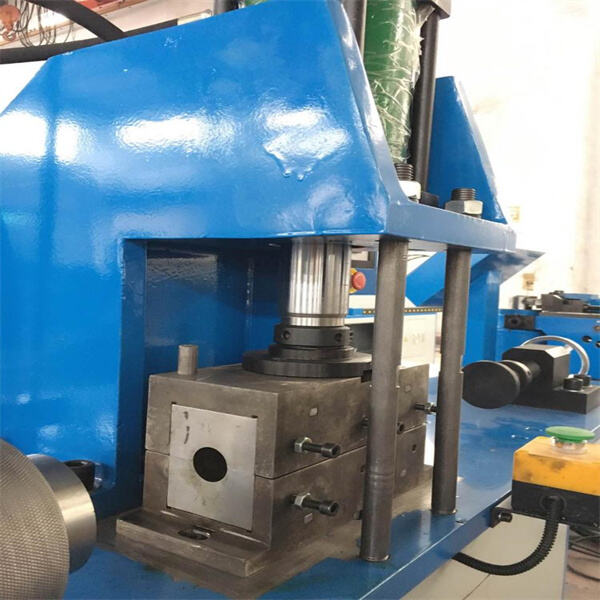

Pipe bending machines are more reliable and Copper benders in production because of the introduction of advanced CNC technology, high speed milling technology and sophisticated control systems. The technological advancements improve the effectiveness of production, as well as the accuracy and quality of the pipe bends. They also meet the processing requirements of various complicated workpieces.

Copper benders machines can be adjusted to the requirements of production through adopting a modular design and optimizing manufacturing processes. This can greatly increase the efficiency of production. The control system is intelligent and monitors production in real time to ensure that the equipment is in top condition. This boosts the efficiency of production.

Pipe bending machine manufacturers provide personalized services that meet particular requirements. They are able to design and build according to the specifications of the client in order to ensure that the angle, accuracy and design of Copper benders are in complete alignment with the requirements of the product. This service is not just tailored to the individual needs of the client and can also enhance the product's quality and efficiency.In summary, pipe bending machine manufacturers give users effective safe, accurate and precise pipe bending options through their technological innovations effective production, safe assurance, energy conservation and environmental protection as well as customized services that meet the needs of different industries and sectors

Pipe bending machine Copper benders are attentive to the safety of operators throughout the design process and adopt multiple safety protection measures including emergency stop buttons safety gratings or infrared devices for protection to ensure the safety of workers throughout the manufacturing process Additionally the machine has a high degree of environmental adaptability and can operate stably in extreme environments providing customers with reliable production guarantees