Ever wondered exactly how metal tubes are so expertly bent to become car exhausts or bicycle frames? Here, in earlier times people where supposed to do this bending manually which was not only a very hard task but also time taking. But now, we have a very special technology: CNC tube bending, the whole process can be much easier and faster!

One big benefit is precision. CNC tube bending machines have a great accuracy. Which lets them put the bends in exactly the right spot, on those metal tubes. This accuracy makes it especially useful in developing consistent high-quality products. With products being made with accuracy, they fit and function properly — this is critical as it pertains to safety and performance.

It also saves a lot of time. Hand bending metal tubes is laborious and time-consuming. However, it is a time-consuming process while CNC machines can perform the same task at higher pace and more efficiently. This simply implies that making more products in less time is possible, allowing factories to operate more effectively and quickly. The increased production capacity of factories means that they can more easily respond to customer demands in an instant.

CNC technology is being employed in a number of different fields and the tube bending industry is no exception. On the other hand, CNC machines were specifically designed to be told what to do without any human intervention concerts. As well as enabling high-speed decision making, this means that workers are freed up to focus on other jobs where more of their skills are required and removes repetitive tasks from them.

Below for everyone to introduce the current CNC tube bending technology, can make the factory work better and faster. These are very fast machines for bending tube and are able to bend many excellent tubes in a short period of time. This speed is so important in today's fast-paced world for companies that want to meet demands.

Its best applications are to create shapes for metal tubing, so it is ideal for CNC tube bending technology. Even highly detailed designs can be created quickly and accurately thanks to this fantastic technology. This is especially crucial in sectors requiring precision such as automotive manufacturing.

Exhaust systems and roll cages require metal tubes shaped in all sorts of strange ways, to give just two examples. This technology gives us the ability to fabricate those parts accurately and fast so they can be produced at the highest level of quality, safety, and reliability. It makes cars less dangerous and more efficient.

Cnc tube bending manufacturers pay attention to the safety of their operators throughout the design process and adopt multiple safety protection measures such as emergency stop buttons safety gratings and infrared devices for protection to ensure the safety of workers throughout the manufacturing process Additionally the equipment has a high degree of environmental adaptability and is able to function safely in conditions providing customers with confidence in their production

Cnc tube bending manufacturers provide tailored services to meet your specific specifications. They are able to design and manufacture in line with the requirements of the customer to ensure that the angle, accuracy and design of bent pipes completely meet the requirements of their product. This custom-made service not only fulfills the specific needs of customers, but also improves the production and quality of the product.In summary Pipe bending machine manufacturers provide users with efficient, accurate and safe pipe bending solutions by virtue of their benefits in technological innovation efficiency, high-quality production, safety security, energy efficiency and environmental protection, and tailored services to meet the requirements of different industries and sectors

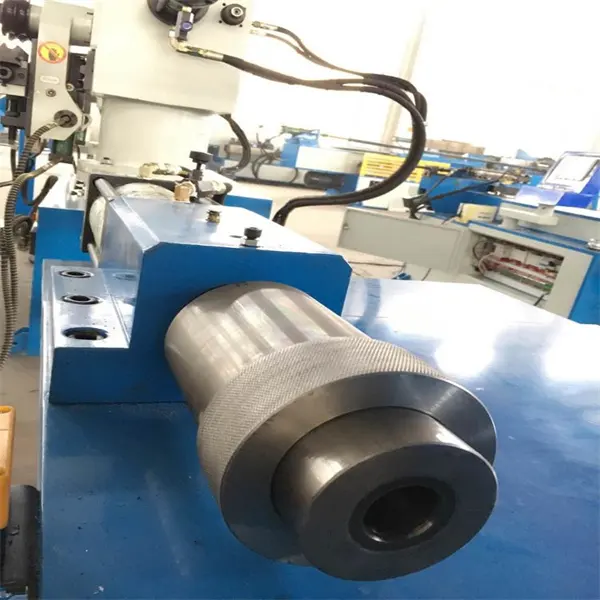

With Cnc tube bending technological advancement pipe benders have introduced modern CNC technology as well as high-speed milling technology and intelligent control systems making the machine more precise and stable during the production process These advancements in technology do not just increase the efficiency of production but also ensure the quality and precision of the pipe bending and fulfill the demands for processing of different workpieces

Cnc tube bending machines can be adjusted to the requirements of production through adopting a modular design and optimizing manufacturing processes. This can greatly increase the efficiency of production. The control system is intelligent and monitors production in real time to ensure that the equipment is in top condition. This boosts the efficiency of production.