Have you ever wondered why can pipes be bent into multiple shapes that are needed to fulfil great plumbing and construction jobs? I cannot imagine the process here, very interesting! In the earlier times, bending of pipes was done only by intense labor using hands and strength. None of which was easy to execute However, today with new machines being around termed as copper pipe benders this stress can be made free of cost and time.

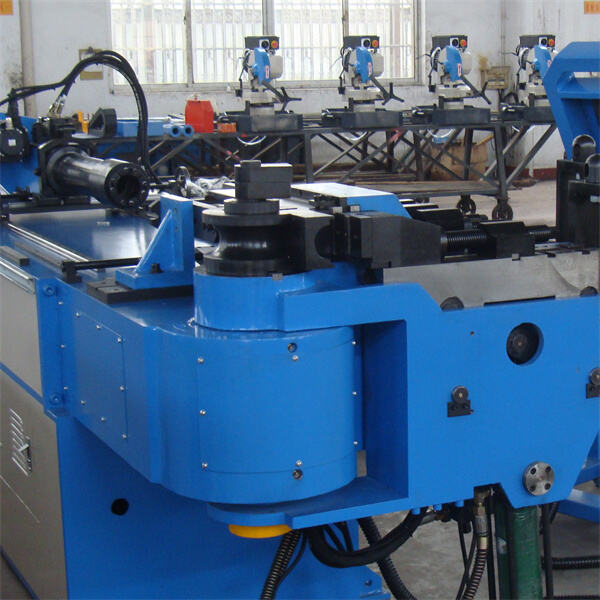

GMACC hydraulic pipe bender is great a machine to bend pipes faster and in precise way. It applies specialized technology to bend pipes exactly the same way as per requirement. This in turn enables workers to bend pipes less by hand, thus saving significant effort. That is where automatic pipe benders can make your task easy and they can help you in making more numbers of pipes in a fraction of time.

There are dozens of reasons to use Automatic Pipe Bender instead of using manual one. Because they are the reason for every single pipe to be bent in the same manner. Furthermore, this is a key step for developing more robust, longer-lasting less leaky pipes Similarly, all the pipes are common, they work best together with any project. Second, they can be used much faster than the human when it comes to bending pipes. This allows for more pipes to quickly and cheaply be made in a factory.

Lastly, the GMACC automatic pipe bender is very easy to use. It can make move to pipe into circular, square and rectangular. This kind of versatility is a massive help in factories and construction sites. We can program the machine to do it just the way we want and therefore much faster and more consistent. This programming capability ensures that workers can program the machine to do other tasks making it highly versatile for different projects.

The GMACC Automatic Pipe Bender Makes It Easier To Bend Pipes You no longer need to break your strength, or ask other people for help. Then, when the machine knows what to do, it can start bending pipes in respectively short times with great accuracy. This allows workers to do the work that puts real money in their pockets rather than spending all day hand-bending pipe. Today, automatic pipe benders have been the very helpful tools for enhancing productivity as factories are continuing to demand more and faster production. For large businesses, they make the production process easier and keep things on the go.

Pipe benders take care to ensure the safety of their operators when designing the machine and adopt multiple safety protection measures like Automatic pipe bender emergency stop buttons or infrared devices for protection to ensure the safety of employees throughout the manufacturing process The machine is also capable of adapting to harsh environments and will work efficiently in harsh environments It provides the user with a confidence in the production

Automatic pipe bender machines can be adjusted to the requirements of production through adopting a modular design and optimizing manufacturing processes. This can greatly increase the efficiency of production. The control system is intelligent and monitors production in real time to ensure that the equipment is in top condition. This boosts the efficiency of production.

Pipe bending machines are more precise and stable in production thanks to the advancement of CNC technology Automatic pipe bender and sophisticated control systems The technological advancements improve the efficiency of production and also the precision and quality of the pipe bends They are also able to meet the demands for processing of various complicated workpieces

Pipe benders manufacturers provide customized services to meet special needs. They are able to design and build according to the needs of the client in order to ensure that the angle, Automatic pipe bender and design of bent pipes fully meets the specifications of their product. This service is not just tailored to the individual needs of the client but also improves the product's quality and efficiency.In sum Pipe bending machine manufacturers give users effective precise and secure pipe bending solutions based on their technological innovations effective production, safe security, energy efficiency and environmental protection and personalized services, meeting the needs of different industries and fields