Are you always tasked to bend pipes and it is not an easy thing to do all by yourself? Sometimes, you may have asked yourself as to how workers and professionals are able to do a number of curved pipes so easily. And how do they manage to pull it off so efficiently, one man could do this job alone, right? – and the answer is they have AC pipe benders! These types of tools have special prongs that result in quickly and easily getting the pipe bent however angluarly correct you need more new to it or inexperienced.

GMACC AC pipe bendersThis product is made of the material that can withstand for a long time. Your projects into the exact shape you require them to be in. That way, you can get creative without worrying about snapping them in the process. Designed to last GMACC AC pipe benders are not something that you buy and you will need another one the following week. They will assist you with various tasks down the line.

This meaning if bending of the pipes makes you tired and it takes a lot of time for you than be relaxed as fully bought at Universities and Colleges. But bankers who use GMACC AC pipe benders get the job done a lot easier. They are also intended to be greek and easy. Anybody can learn to use the pipe bender: you just have to get in some practice and do not be afraid to ask for help. If you want to bend pipes without any hassle, using GMACC AC pipe benders! You will come to feel more confident and tooled-up when you go about your work.

GMACC AC pipe benders help you make perfect bends every time. They achieve perfect bends by using the same technology on their 3D-printed pipes. Don't lose hope, GMACC-AC Pipe Benders can make whatever bends you require at the proper design angles and shapes for your project. No more sags identified with your bends and poorly shaped pipes. You work will be neat and professional, which is what we all want to happen when doing a project with self-locking benders.

They also feature GMACC AC pipe benders to enable you work so fast. These machines are ideal in environments where a lot of work has to be done and can quickly bend pipes. Choose the right tools and get things done on time, every step of the way. Although with GMACC AC pipe benders, you get to land your job pretty neat and clean within no time resulting in tons of finished products without consuming hours. Meaning more success for your or your business!

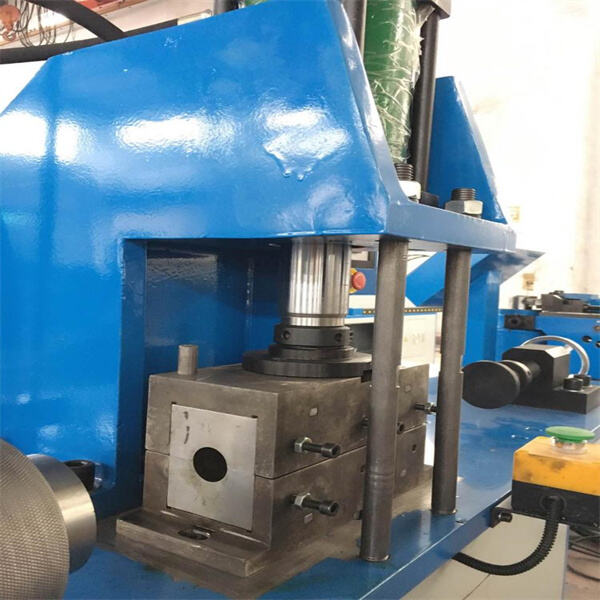

Pipe bending machine manufacturers provide personalized services that meet particular demands. They can develop and produce the product according to the needs of the client, ensuring that the Ac pipe benders, accuracy and design of bent pipes are in complete alignment with the specifications of the product. This service is not just designed to meet the needs of the customer however, it also improves the efficiency and quality of the product.In short Pipe bending machine manufacturers provide users with efficient safe, accurate and precise pipe bending solutions based on their advantages in technological innovation, efficient production, safety security, energy efficiency and environmental protection and personalized services, meeting the demands of different fields and industries.

Pipe bending machines are easily modified to meet the demands of the production process by adopting a modular design and Ac pipe benders. This dramatically improves production efficiency. The system of control is intelligent, and continuously monitors production to ensure that the equipment is operating in good condition. This enhances efficiency in production.

Ac pipe benders have become more accurate and stable in production because of the development of modern CNC technology high-speed milling technology and sophisticated control systems These advances in technology not only enhance the efficiency of production however they also guarantee the quality and accuracy of the pipe bend and meet the processing needs of various complicated workpieces

Pipe bending machine Ac pipe benders are attentive to the safety of operators throughout the design process and adopt multiple safety protection measures including emergency stop buttons safety gratings or infrared devices for protection to ensure the safety of workers throughout the manufacturing process Additionally the machine has a high degree of environmental adaptability and can operate stably in extreme environments providing customers with reliable production guarantees