Bender 1 1 4: This is a little tool that helps bend tubes. The product is very useful for people who need tubes bend at various shapes as well as angles. The tool was engineered and developed by GMACC as an approach to enable everyone with an easier and faster tube bending necessity. Either eject you are a DIY fan otherwise industrial worker, this bender bottle makes your effort more relaxed and time-saving.

To get started, you will select the tube to bend. You Must Confirm the tube fits in the 1 1 4 Tube Bender Even though the tube may be chosen with reference to a length that bends at 45k in an accurately shaped manner, if it does not fit well, it will not bend correctly. Pick your tubeAfter making what length of tube to use you will need to pick out the exact spot you want to bend it at. Highlight the area that you want to bend with a pencil or a marker.

Put the tube into the bender carefully. Next Ensure the mark spot is right in position inside the tool. The mark being in the right place is imperative — that should be the point where you are bending. Then you knock it in just a little and into the bender. Continue to twist and bend the tube until it has formed into your desired shape. Lightly press the tube with your hands. And keep pulling until it is completely bent to your will.

Get the most perfect bend by ensuring you have the right angle for your tubing. You must maintain the same angle you selected for the bending process entirely. That makes you have to do this carefully. Checking within a protractor or with rule черновика This will help you in ensuring whether you have the accurate measurement before bending.

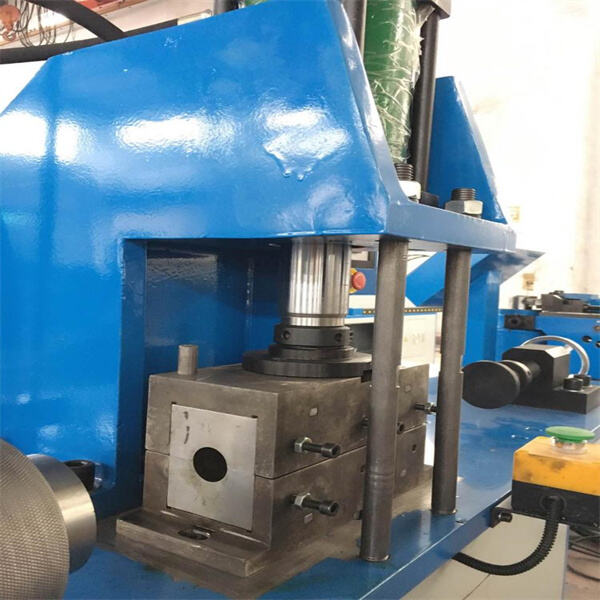

The 1 1 4 Bender operates with the use of two rollers that clamp down on the tube. These rollers exert pressure directly onto that line where you have marked the tube to bend it. These rollers move and aid to bend the tube in that place exactly. You will determine the bend degrees you create due to the position of your rollers and their distance between them. This knowledge will also help you to make better bends.

What I will be reviewing today is the 1 1 4 Bender, and it will only appeal to people that love making new things. Never forget you can form tubes at many shapes and angles to create unique designs than tube is a star in engineering. For instance, it might be the tool to craft an amazing metal sculpture with or the ideal bike frame that fits you exactly. With this tool, you can be creative and create everything you want.

Occasionally, the tube gets a kink or flattens out when using a 1 1 4 Bender. If you push too hard, or use too little lubricant on the tube this can occur. Applying lubricant allows the tube to slide easily without any harm. Well, just put enough lube on the tube and this will not be a problem. Also, please be aware that while you push the tube, do not put undue force because it could lead to some problems and you will lose all your hard word.

By optimizing the production process and adopting a modular design pipe bending machine makers can easily adjust the machine according to production needs drastically increasing efficiency At the same time the 1 1 4 bender monitors the process of production in real-time ensuring that the equipment is always in the best condition further improving production efficiency

The manufacturers of pipe bending machines take care to ensure the safety and security of the workers in the process of designing They adopt multiple safety measures for example safety gratings 1 1 4 bender and infrared safety devices to guarantee their security during production The machine is also capable of adapting to harsh environments and performs well in these environments This provides users with confidence in the production

With constant 1 1 4 bender, pipe bending machine manufacturers have introduced modern CNC technology, high-speed milling technology and intelligent control systems, making the machine more precise and stable during the production process. These advancements in technology do not just increase the efficiency of production however, they also guarantee the quality and accuracy of the pipe bending, and meet the processing needs of various complicated workpieces.

1 1 4 bender of pipe bending machines offer customized services to meet special demands. They can design and build according to the specifications of the client to ensure that the angle, precision and the shape of bent pipes fully meets the specifications of their product. This service isn't only custom-designed to meet the requirements of the client but also improves the quality of the product and its efficiency.In sum, pipe bending machine manufacturers provide their customers with reliable safe, accurate and precise pipe bending solutions by virtue of their technological innovations and efficient production, as well as safety security, energy efficiency and environmental protection and personalized services, meeting the needs of different industries and fields