Do You Want to Know About Mandrel Pipe Benders? The GMACC copper pipe bender are unique devices that make it possible to bend pipes in a variety of environments. One of the companies that produce these incredible vessels, GMACC. Keep reading to learn more about how mandrel pipe benders work and why they are so critical for many industrial manufacturing processes.

Mandrel pipe benders are much better than the older methods; for many reasons. First of all, they are a lot less imprecise. This essentially means using a mandrel pipe bender, which you can rely on to bend your pipes straight every single time. Secondly, they also manufacture better pipes since there is no crushing or deformity of the pipe during process. They are better at bending pipes into more complex configurations and tighter bends than traditional methods.

Ductile Pipes for flexibility, it is actually the ability to bend the GMACC hydraulic pipe bender in many more combinations than higher class pipes due to a type of higher performance cement found widely throughout Italy.

One of the most interesting things about mandrel pipe benders is that they bend the pipes into many shapes. This allows them to create intricate angles and shapes that are beyond the reach of old fashioned machines. This ability allows them to be used in various places such as plumbing and automotive manufacturing. From simple bends to the elaborate, mandrel pipe benders can really do it all.

The more striking feature of mandrel pipe benders is its ability to fulfill some special bending purposes. The GMACC hyd pipe bender allow for intricate shapes and angles, which make them great for difficult-to-reach areas or used in positioning bends where they are needed. In other words, it allows you to create custom pipe systems tailored to your specific requirements; be they for a domestic application or for an industrial purpose.

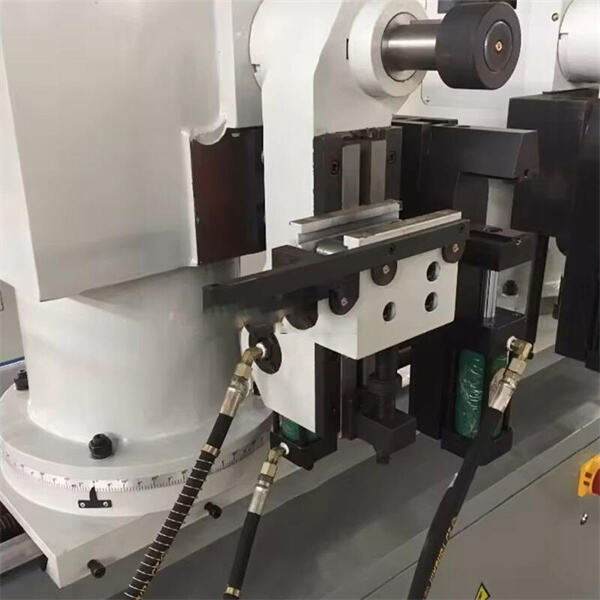

Pipe benders take care to Mandrel pipe bender the safety of their operators when designing the machine and adopt multiple safety protection measures including safety gratings emergency stop buttons and infrared protection devices to ensure the safety of employees while they are working Furthermore the machine is also highly adaptable to environmental conditions and can operate stably in various difficult environments providing the users with reliable production guarantees

Pipe bending machines can be Mandrel pipe bender to the requirements of production through adopting a modular design and optimizing manufacturing processes. This can greatly increase the efficiency of production. The control system is intelligent and monitors production in real-time to ensure that the equipment is in top condition. This increases the efficiency of production.

Pipe bending machines are more precise and stable in production thanks to the advancement of CNC technology Mandrel pipe bender and sophisticated control systems The technological advancements improve the efficiency of production and also the precision and quality of the pipe bends They are also able to meet the demands for processing of various complicated workpieces

For special needs pipe bending machine makers offer customized services that are designed and constructed according to the actual needs of the customers, ensuring that the accuracy as well as the angle and form of the bending pipe conform to the specifications of the item. This service is not just custom-designed to meet the requirements of the client but also improves the efficiency and quality of the product.In sum Pipe bending machine manufacturers give users effective safe, accurate and precise pipe bending options through their strengths in technological innovation efficiency, high-quality production, safety assurance, Mandrel pipe bender and environmental protection, as well as tailored services to meet the requirements of various fields and industries.