Do you want faster and better pipes? In that case, semi-automatic pipe bending is what you are looking for! This novel technology assists pipe manufacturers in producing the right pipes without excessive extra effort. It’s an intelligent way to manufacture quality pipes efficiently and accurately.

Accurate Bends: Semi-automatic pipe bends are incredibly wise and that's one of their best qualities. They’re able to make exactly right bends every single time. That means you don’t need as many workers doing the bending by hand, which can take lots of time and lot of effort. The machines do this work accurately, which results in a better and more efficient production.

Save Time and Money: Another great advantage is that semi-automatic machines do a more extensive job in little time. They assist in decreasing the time needed to manufacture pipes overall that helps you to minimize your production cost. You can also save money on paying these people too as you need fewer of them to do the bending which means more savings for your company.

More Options: Semi-automatic machines are very flexible. They can manufacture various pipe types, from shaping, sizing, and types of material. This means more options for pipe makers and the ability to create what they need to fit many different projects. In today’s market, being able to produce a variety of pipes is a huge advantage.

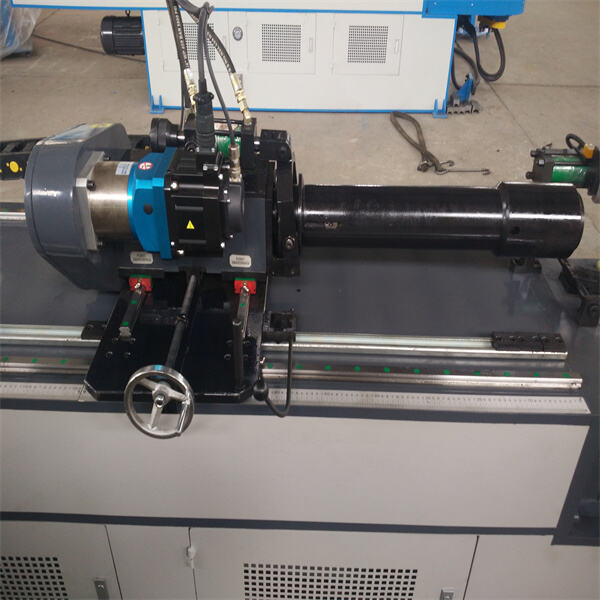

This machine is one of many semi-automatic pipe bending machines available at GMACC, and they will fulfill your needs. We build our machines with the newest technology with your unique pipe-making needs in mind. Equipment that serves us will not only facilitate our work, but will also save valuable time.

The use of machines is being adopted as many factories are able to take advantage of their working capabilities and efficiencies. Stay competitive in a fast-paced world by utilizing GMACC semi-automatic pipe bending machines to help maintain the presence required to succeed. Integration of manufacturing in Artificial Intelligence is the primary step to success.

To sum up, a semi-automatic pipe bending machine is an excellent new method to assist you enhance your pipe-making expertise. The numerous advantages of them include; helping you create exact bends, saving your time & money, giving you more options & producing less waste. Need to improve your production process for better productivity? GMACC has the machines for you.

Through continuous technological innovation, semi automatic pipe bending have developed advanced CNC technology with high-speed milling technologies and intelligent control systems, making the machine more precise and stable throughout the production process. These advancements in technology do not just increase the efficiency of production but also guarantee the quality and precision of the pipe bending and meet the processing needs of various complex workpieces.

Pipe benders manufacturers provide customized services to meet special needs. They are able to design and build according to the needs of the client in order to ensure that the angle, semi automatic pipe bending and design of bent pipes fully meets the specifications of their product. This service is not just tailored to the individual needs of the client but also improves the product's quality and efficiency.In sum Pipe bending machine manufacturers give users effective precise and secure pipe bending solutions based on their technological innovations effective production, safe security, energy efficiency and environmental protection and personalized services, meeting the needs of different industries and fields

Manufacturers of pipe benders take care to ensure the safety and protection of the operators in the process of designing. They adopt semi automatic pipe bending, like safety grates safety gratings, emergency stop buttons, as well as infrared safety equipment, to ensure their safety throughout production. The equipment is also highly flexible to harsh conditions and will work efficiently within them. It provides the user with a confidence in the production.

Pipe bending machines can be easily adaptable to the demands of production using an modular design and optimizing the production process. This can greatly increase the efficiency of production. semi automatic pipe bending, the intelligent control system monitors the process of production continuously to ensure that the equipment is in good working order which further improves the efficiency of production.