Ever wonder how a pipe is made? Pipes are a daily necessity in our life. They assist in plumbing that provides water supply in households and further more give wayfor movement of things which has gas and water, from the place where it is originated to the place for consumption. The entire process is made more effective, with the aid of a pipe bending machine that assists in cutting and shaping pipes immediately.

Something neat about the machines from GMACC is that they can stand alone. This is called automation. This means the machines are able to cut and shape pipes automatically without help from humans. It is more important because it can make machines work continuously without being tired. This automation results in more accurate pipes, so they will work better together when they are installed.

INNOVATING THE PIPE MAKING INDUSTRY -Watching these round machines take shape at GMACC has definitely been mind blowing! These machines are used by companies all over to pump out the finest-quality pipes possible. GMACC allows companies to work more efficiently and faster without their newest technology, sounds good for business right? This implies that they can produce a larger amount of pipes in less time, hence addressing the operation demands of customers.

If you want your pipes to be better, please use GMACCs round machines. They were created to assist pipe makers of the modern era. These are some of the user-friendly and durable machines that utilize less time and resources{id=34022 /} They are very accurate and this results in the smooth functioning of the manufacturing process through quality products.

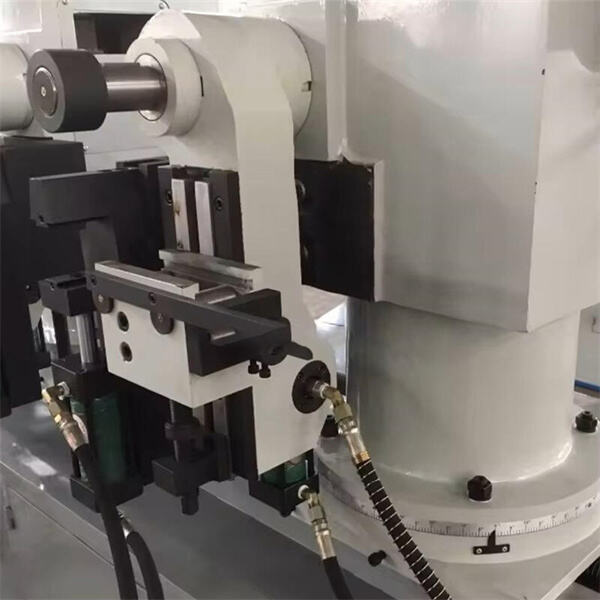

GMACC has developed machines as camera type equipment, capable of modeling a pipe in various shapes and dimensions thanks to the latest round machine technology. This is an important aspect as projects may vary in terms of pipe types needed. They are also energy-efficient, which results in cost savings for the companies with their electricity bills. The machines at GMACC are intelligent equipment that assist business in coping with the futureunicipGridView.Comparator

The use of GMACC's machines is also beneficial as it allows for more pipes to be produced on a fast turnaround. We build machines that operate quicker and with increased skillfulness than ever before. In other words, companies can set up more pipes in shorter time — an excellent method to ramp up production. This results in more sales and happier customers because you can produce more pipes way faster!

Thus the pipe cutting machines are equipped with top performing range so it will gives quality results. But accurate, so the pipes made are strong and break less often. It means fewer repairs, which saves the companies utilizing them less time and money. Unsurprisingly, pipes that can take a beating lead to less issues and more satisfied customers.

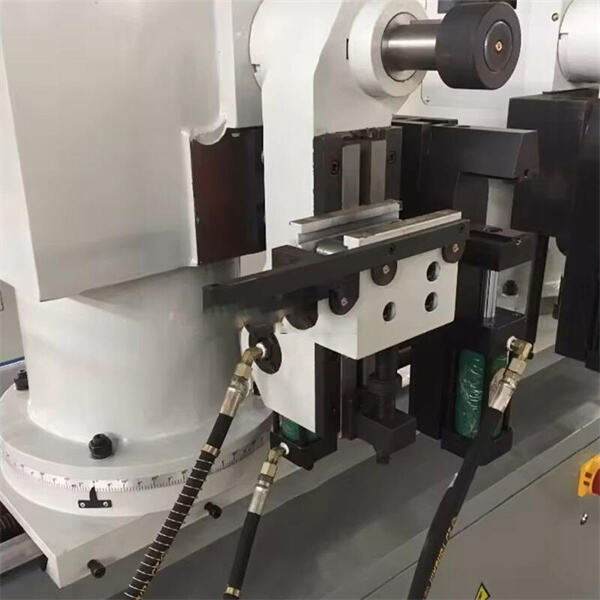

Pipe benders take care to ensure the safety of their operators when designing the machine and adopt multiple safety protection measures like Pipe round machine emergency stop buttons or infrared devices for protection to ensure the safety of employees throughout the manufacturing process The machine is also capable of adapting to harsh environments and will work efficiently in harsh environments It provides the user with a confidence in the production

By optimizing the production process and adopting a modular design pipe bending machine manufacturers can easily adjust the machine according to production demands, Pipe round machine improving production efficiency. While at the same time the control system's intelligent technology controls the manufacturing process continuously to ensure that the equipment is in top condition and thereby increasing the efficiency of production.

In constant technological development, pipe bending machine manufacturers have developed advanced Pipe round machine, high-speed milling technology and sophisticated control systems that make the equipment more accurate and stable during the manufacturing process. The technological advancements improve the efficiency of production as well as the precision and quality of pipe bends. They also meet the requirements for processing of different complex workpieces.

Pipe bending machine manufacturers provide personalized services that meet particular requirements. They are able to design and build according to the specifications of the client in order to ensure that the angle, accuracy and design of Pipe round machine are in complete alignment with the requirements of the product. This service is not just tailored to the individual needs of the client and can also enhance the product's quality and efficiency.In summary, pipe bending machine manufacturers give users effective safe, accurate and precise pipe bending options through their technological innovations effective production, safe assurance, energy conservation and environmental protection as well as customized services that meet the needs of different industries and sectors