GMACC is thrilled to present to you the pipe and tube benders of 2021! Whether you are a plumber or just enjoy fixing things around the house, having plumbing tools is essential. The correct tools can simplify your task as well as allow you to perform better. A pipe bender is one of the most important tools. A pipe bender gets bent metal pipes in a way that they are not wrinkled or damaged. Store bought pipe benders come in a variety of versions, which makes it hard to choose the correct one for your task. That’s why we’ve scrutinized the best pipe benders and chosen our favorites to help you make a wise selection.

There are two main types of pipe benders: manual and hydraulic. Manual pipe benders are hand-operated; you will manually use your strength when bending the pipe. On the other hand, the hydraulic pipe benders employ special pressure to produce the bending, which is easy to deal with even in harder materials. Both varieties have their pros and cons depending on the type of work you need to perform.

The GMACC Pipe Bender Tool is an example of the top manual pipe bender. This tool for bending different types of pipes including copper, aluminum or thin steel pipe. It also bends pipes to 180 degrees without damaging the pipes. This pipe bender is great in that it is small and compact, so you can take it with you when you do home projects or plumbing jobs. If you need to move it to different places, it is also easily portable.

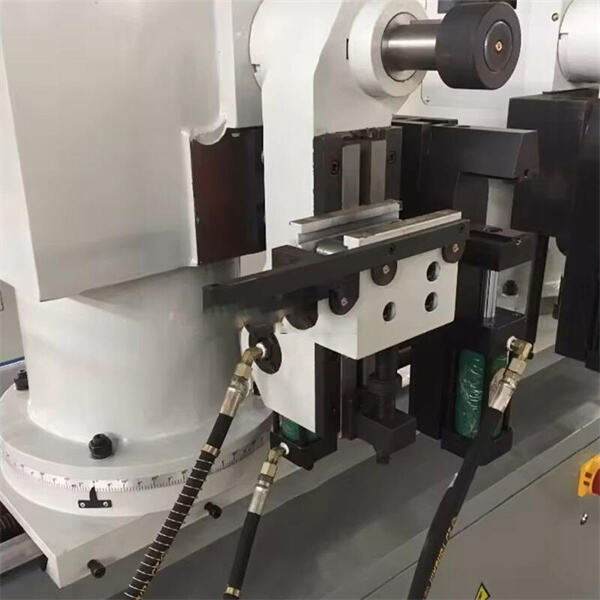

The GMACC Hydraulic Pipe Bender is our best pick if you're looking for a hydraulic pipe bender. This tool is great for bending thicker and stronger pipe that needs more strength to bend it. It has a foot pedal, which means it is very user-friendly. The foot pedal lets you control the bending and frees your hands to ensure you get what you want without beating your head against the wall.

A pipe bender is an excellent investment in the world of pipe forming tools; when you decide to buy a pipe bender, it is necessary to consider its features and how they would work in your favor. Before you buy, however, here are some critical points to keep in mind:

Capacity: Ensure the pipe bender specs match with the size and thickness of the pipes that you will be using. Depending on the project, you might need this smaller or larger so check this very carefully.

Flexibility: A good pipe bender can bend a variety of different types of materials. Depending on the model, some pipe benders are capable of handling copper, aluminum, or even steel, which will leave you plenty of options when selecting materials to work with.

best pipe bender of pipe bending machines offer customized services to meet special demands. They can design and build according to the specifications of the client to ensure that the angle, precision and the shape of bent pipes fully meets the specifications of their product. This service isn't only custom-designed to meet the requirements of the client but also improves the quality of the product and its efficiency.In sum, pipe bending machine manufacturers provide their customers with reliable safe, accurate and precise pipe bending solutions by virtue of their technological innovations and efficient production, as well as safety security, energy efficiency and environmental protection and personalized services, meeting the needs of different industries and fields

best pipe bender manufacturers pay attention to the safety of their operators throughout the design process and adopt multiple safety protection measures such as emergency stop buttons safety gratings and infrared devices for protection to ensure the safety of workers throughout the manufacturing process Additionally the equipment has a high degree of environmental adaptability and is able to function safely in conditions providing customers with confidence in their production

best pipe bender machines can be adjusted to the requirements of production through adopting a modular design and optimizing manufacturing processes. This can greatly increase the efficiency of production. The control system is intelligent and monitors production in real time to ensure that the equipment is in top condition. This boosts the efficiency of production.

Continuous technological innovation has led to pipe bending machine manufacturers have introduced modern CNC technology high-speed milling technology and intelligent control systems making the equipment more best pipe bender and stable during the manufacturing process These advances in technology not only improve efficiency in production but also guarantee the quality and precision of the pipe bending and meet the processing needs of various complex workpieces